Predictive Maintenance of Vehicles

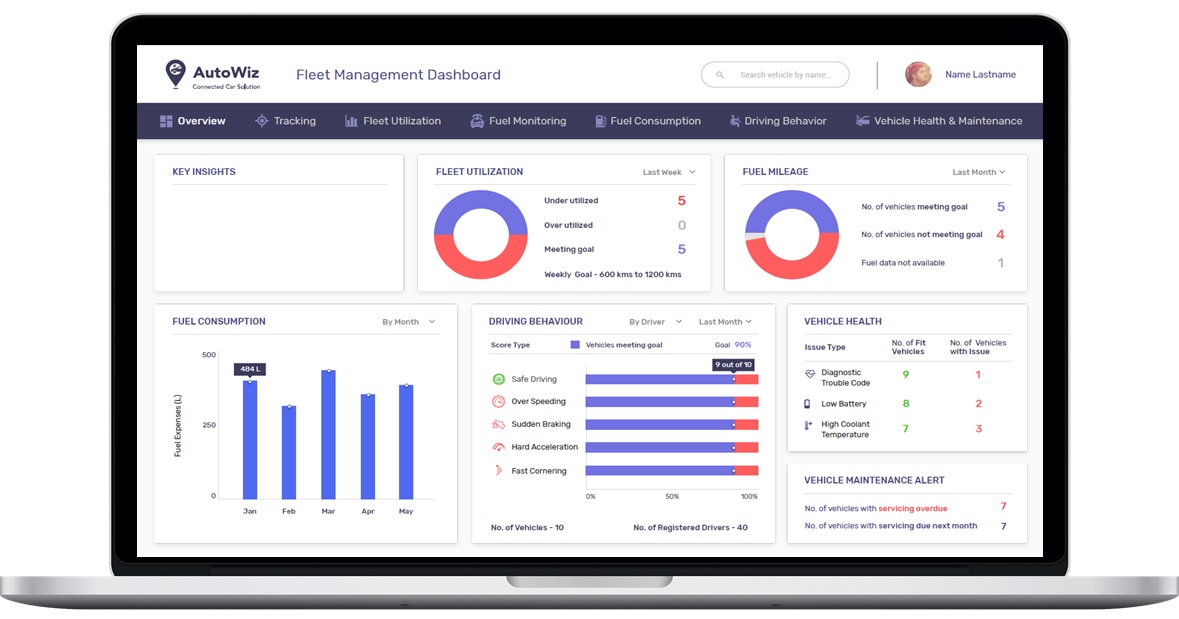

For Fleet owners running a fleet of vehicles, managing the preventive and scheduled maintenace of vehicles is a non-trivial job. However, often these scheduled maintenance activities overlook the underlying issues that may result in unexpected breakdowns down the road. On the other hand, some of these scheduled maintenance activities might end up over-doing service on parts which may not have been needed. Whats needed is a more nuanced, customized and dta driven approach in deciding what to service and when to service so as to optimize maintenance cost and prevent unexpected breakdowns.

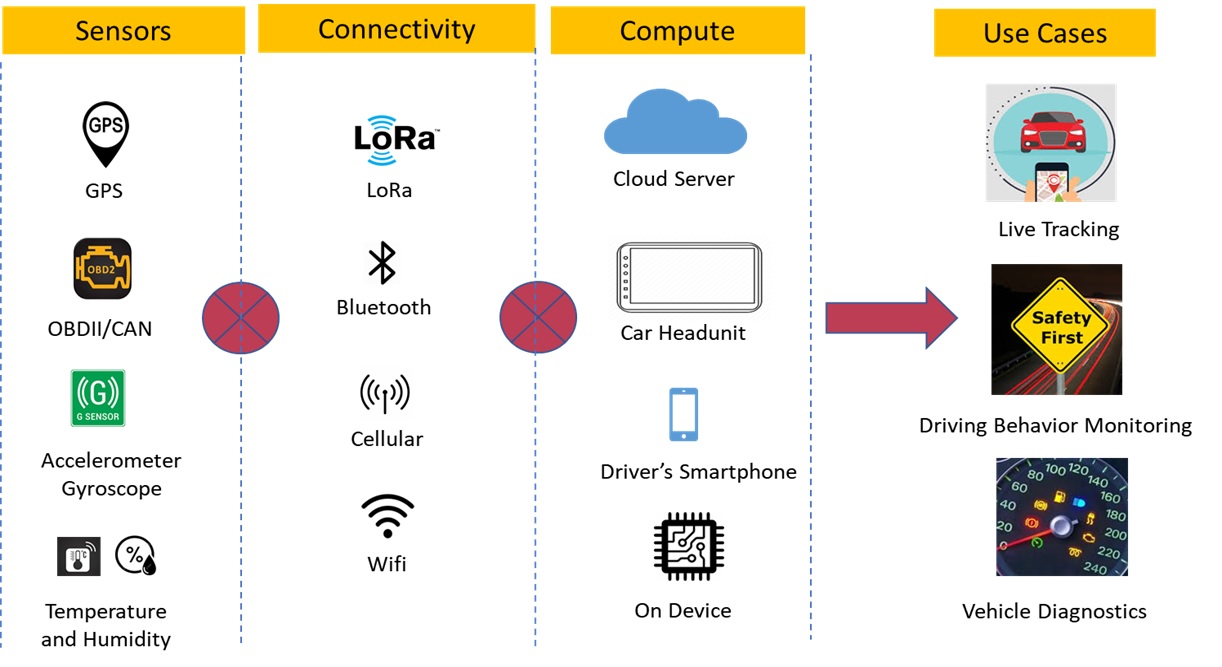

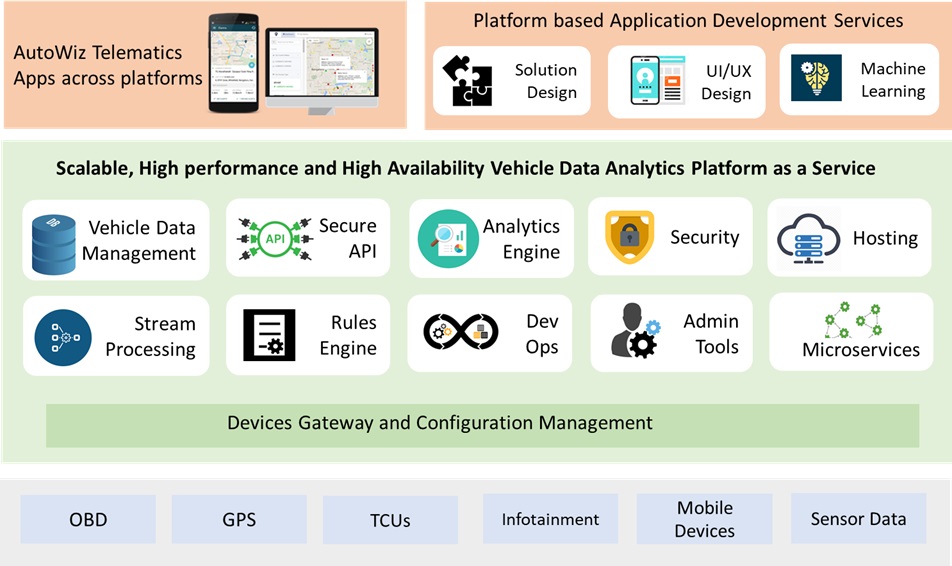

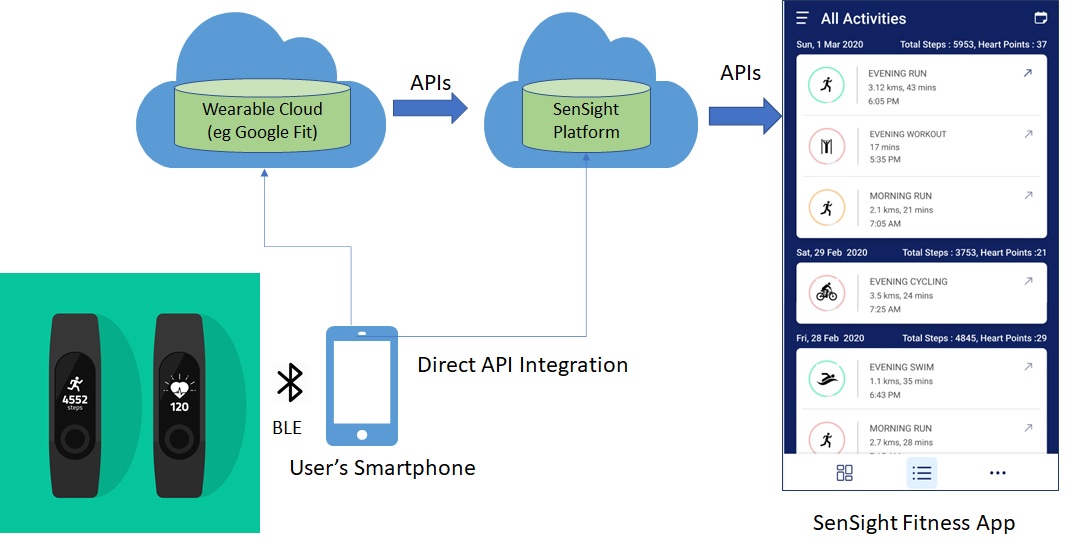

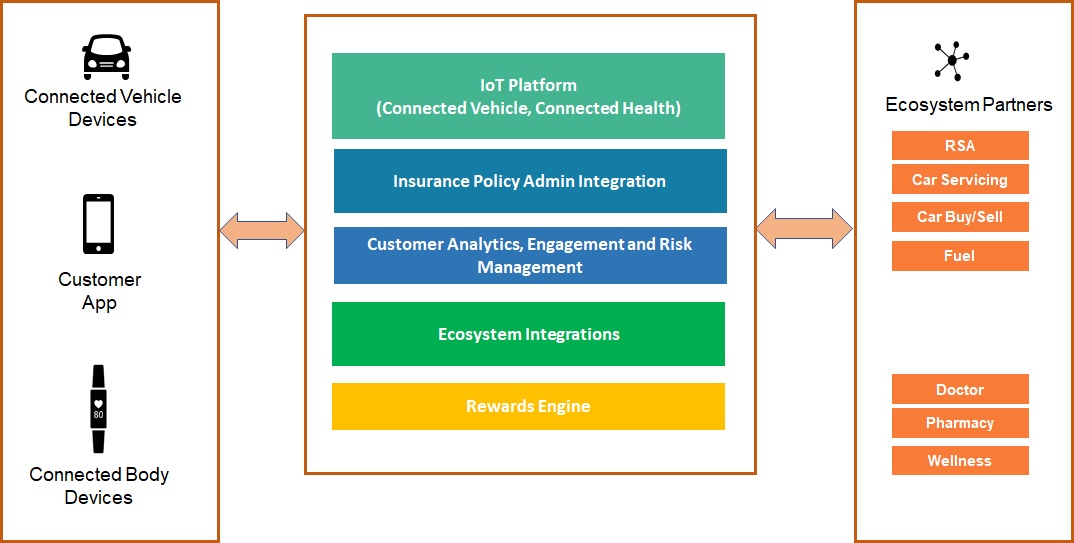

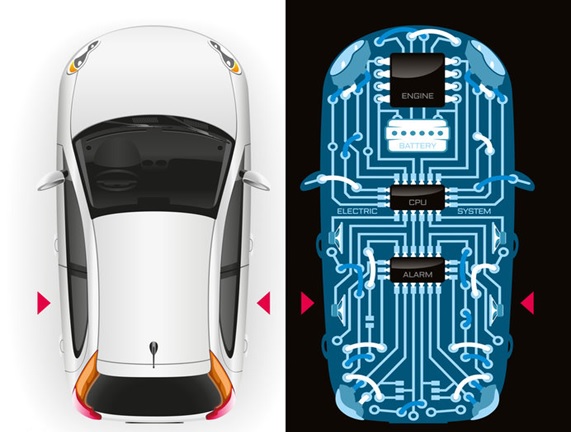

SenSight's AutoWiz Connected Vehicle Platform enables such data driven approach to fleet maintenance and offers descriptive diagnostics and predictive maintenance solutions leveraging OBD/CAN data.

OBD Diagnostics based Vehicle Inspection and Maintenance Report

Using On-board Diagnostics (OBD) devices plugged into vehicle, we generate an objective diagnostics report rating the various engine susb-systems, performance and maintenance parameters of the vehicle

- Objective Rating Report based on just 5 minutes of test drive data captured using connected OBD Device

- Comprehensive Report includes rating across various performance and maintenance parameters including Fuel Mileage, Power, Battery Condition, Coolant, Load, Idle RPM and Oxygen Sensors

- Diagnostic Trouble Codes (Fault codes) classified as per specific subsystem, likely component and severity level to help Fleet Manager take timely action

- Uses proprietary rating algorithms and insights derived from AutoWiz’s Historical Data of similar car make/model collected over years

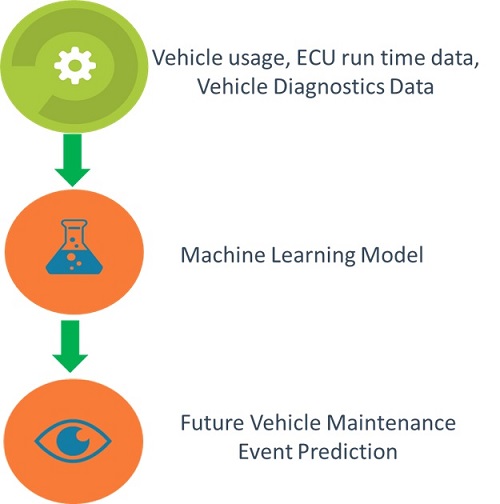

Vehicle Maintenance Event Prediction

SenSight has developed a vehicle maintenance prediction model to predict certain maintence events

Model uses the run-time time series data of vehicle usage and ECU data (from OBD) from a vehicle to predict a maintenance event in future. Depending upon nature of event being predicted, uses supervised and un-supervised machine learning techniques to predict likelihood of a part failure.

As an example, Model is used to predict likely fault in the Turbocharger subsystem of a Diesel vehicle. A Turbocharger increases an internal combustion engine’s efficiency and power output by forcing extra air into the combustion chamber.

By monitoring the Pressure of Air entering into the engine obtained via the Manifold Absolute Pressure (MAP) sensor, we find that under acceleration conditions (increasing RPM), MAP of a defective car shall be lower than MAP of healthy car. Such anamolous behavior detected using the run-time OBD data enables one to predict a Turbocharger fault.

Value Proposition for Customers

Such IoT enabled Descriptive and Predictive Maintenance of Vehicles is great for Fleet owners by giving them accurate guidance on scheduling repair/maintenance before breakdown occurs.

Its also relevant for Vehicle OEMs and Tier-1 Suppliers to monitor trending problems, reduce warranty costs, recalls and improve performance.

For Used Car Dealers and Platforms, such solutions help provide an unvarnished, objective valuation of vehicle based on real car condition data.

Case Studies

Browse through some of our recent work in the domains of IoT, AI/ML and Cloud.

- All

- IoT Device

- AI and ML

- Cloud and Big Data

- Web and Mobile App